What Is a Wiring Harness?

The processes involved in creating a wiring harness are often more difficult to automate than other types of cable assemblies. This is because they require fine motor skills that are hard to replicate with machines.

Examples include cutting and identifying individual wires, stripping the insulation to expose the uninsulated conductor, crimping terminals onto the end of the wire, and applying wraps and ties. Quality testing is also required.

What is a Wiring Harness?

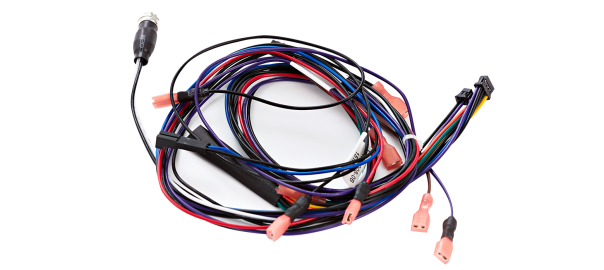

A wiring harness is a group of cables or wires that are designed to carry signals, data or electrical power. They are typically used in a wide variety of applications including: aerospace, automotive, medicine, telecommunications, commercial buildings and more. They are a cost-effective alternative to loose wires or cables, and can help engineers and designers create and organize their wiring systems more efficiently.

Wiring harnesses differ from cable assemblies in that they do not focus on providing added protection for the wires or cables, compared to a high-level of resistance to outside variables. Instead, they are primarily used to keep electric cables and wires organized. This allows them to remain free of tangles and helps protect the wires and cables from external environmental elements such as dust, moisture, friction or heat.

Whether you are looking for a simple wiring harness or something more complex, we can build it to your specifications using blueprints or schematics. Our highly trained technicians will make sure it meets all requirements to ensure safety, reliability and performance.

To begin, a 2D representation of all the wiring designs are created in software to show how each wire will be bundled together and connected to end terminals or connector housings. These details can then be imported into a 3D tool to add passive components such as straps, cable ties, cable lacing, sleeves and electrical tape to relevant areas of the wiring harness. Once the design is finalized, the production process begins in the cutting area, then moving on to pre-assembly and finally assembly.

Wiring Harness Types

There are many different types of Wiring Harness wire harnesses, each suited to specific applications. However, the three fundamental components of wiring harnesses are wires, connectors, and terminals. Each plays an important role in ensuring that the finished product has continuity and integrity, as well as safety.

Wires are essential to creating electrical circuits, but it’s important that they can withstand environmental conditions and mechanical stress. For example, a wire should have good abrasion resistance to minimize damage from rubbing or scraping. Additionally, it’s important that a wire is able to withstand varying temperatures. This can be achieved by using a material that has thermal expansion and contraction properties.

Connectors are electromechanical devices that provide a secure and reliable connection between conductors. They can be made of a variety of materials, including metals and plastics. In addition, they can be insulated or uninsulated. They are also available in a wide range of shapes, sizes, and designs. Examples include hooks, rings, spades, and bullet terminals.

Wire harnesses require a significant amount of time and effort to install. When these cables and small parts are consolidated into a single harness, it can save a huge amount of manufacturing time, as well as reduce the chance for human error. In addition, harnesses can help to protect the wires from environmental factors, such as corrosion and EMI.

Wiring Harness Applications

A wiring harness can be used in a variety of ways. For example, it can be utilized in the construction of electrical equipment and devices to ensure that the correct connections are made between the various components. It can also be used in the automotive industry to provide power and signal conductors that are needed for the efficient functioning of an automobile.

Wiring harnesses are often made from durable materials that can withstand the harsh conditions found in many industrial and automotive environments. They can also help to reduce the risk of wires becoming disconnected and creating an electrical short circuit by binding them together into a non-flexing bundle.

The electrical characteristics of a wiring harness are typically tested using a special test fixture. The testing procedure can determine whether the electrical characteristics of a harness meet all applicable industry and safety standards. The test can also help to identify any issues that may need to be addressed, such as ensuring that all terminals are properly seated in the connector housing.

Wiring harnesses can be built and incorporated into electrical equipment by a wide range of manufacturers, including both large and small businesses. The process of building a harness involves cutting and identifying individual wires, routing them through any required sleeves, applying wraps and ties to prevent wires from moving around during operation, and crimping or soldering terminals onto the ends of wires. Some of these processes can be automated, but for the most part, building a harness is still largely done by hand.

Wiring Harness Components

Wiring harnesses are used in a variety of industries, including aerospace, automobiles, medicine, and telecommunications. They provide a number of benefits, such as improving safety, reducing the risk of electrical fires, and simplifying installation.

Some of the main components of a wiring harness are cables, connectors, terminals, and insulating covers. The wires in a cable harness are grouped together to save space and make it easier for workers to identify them. Connectors and terminals are then attached to the individual wires. Generally, they are made of metals such as copper or brass to ensure that they can handle the voltage being passed through them.

Cable ties and clamps are also used to keep the wires in place Wiring Harness and prevent them from tangled with one another or other equipment. They also help to protect the wiring from moisture, which can cause electrical shorts and fires.

Locks can be added to a cable harness to prevent accidental disconnection and short circuits by keeping the terminals closed until they are opened or removed. These locks are a critical part of ensuring that the wires in a harness remain properly connected and adhere to manufacturing standards.