Polymer Lithium Battery: Advantages, Manufacturing Methods and Selection Guide

Manufacturing methods:

Polymer lithium bat

teries, also known as LiPo batteries or PLB (abbreviation for Polymer lithium battery), are a type of rechargeable battery that has gained significant popularity in recent years. Unlike traditional lithium-ion batteries, polymer lithium batteries use a gel-like electrolyte PLB (abbreviation for Polymer lithium battery) instead of the liquid electrolyte found in standard lithium-ion batteries.

The manufacturing process begins by first preparing the positive and negative electrodes. The positive electrode is typically made from a mixture of powdered positive active materials such as lithium cobalt oxide or iron phosphate, conductive additives, and a binder material like polyvinylidene fluoride (PVDF). On the other hand, the negative electrode con

sists of graphite with conductive additives and binders.

Once the electrodes are ready, they are coated onto metal foils using various coating techniques such as doctor blade coating or slot-die coating. Afterward, these coated foils are pressed together with a separator layer in between to form a sandwich-like structure. This structure is then rolled up tightly to create a small-sized cylindr Lithium-ion polymer battery ical cell or stacked into larger prismatic or pouch-shaped cells.

The final step involves filling the cell with the gel-li

ke electrolyte through injection or vacuum impregnation methods. Once filled, the cell undergoes several cycles of charging and discharging to enhance its performance before being packaged into finished battery products.

Characteristics and advantages:

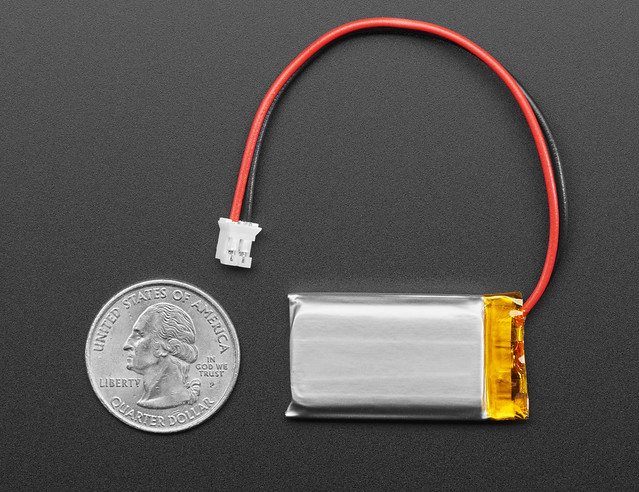

Polymer lithium batteries have several key characteristics that make them highly desirable for various applications. Firstly, their flexible packaging allows for customizable shapes and sizes to fit different devices’ requirements better. This flexibility distinguishes them from rigid cylindrical cells comm lifepo4 lithium battery only found in traditional lithium-ion battery designs.

Additionally, polymer lithium batteries exhibit excellent stability thanks to their solid-state design which eliminates concerns regarding leakage of liquid electrolytes under extreme conditions. Their self-discharge rate is also relatively low compared to other types of recha polymer lithium battery rgeable batteries, making them suitable for long-term energy storage applications.

Usage and selection guide:

When using polymer lithium batteries, it is essential to consider the specific charging and discharging Lithium battery customization requirements of the device they will power. Manufacturers often provide datasheets with recommended operating parameters such as voltage limits, temperature ranges, and maximum current ratings. Adhering to these guidelines can help maximize the battery’s lifespan and overall performance.

To select the most suitable polymer lithium battery for a particular applicati Solar Lithium Battery on, one should evaluate several key factors. These include capacity requirements (mAh), voltage compatibility with the device, weight limitations if any, operating temperature range of both the device and battery itself, and charging interface options (USB or proprietary connectors).

It is also crucial to verify the r LiPo battery eliability of the manufacturer by checking certifications like CE (Conformité Européene) or UL (Underwriters Laboratories). Moreover, reading customer reviews or seeking recomm polymer lithium battery endations from trusted sources can further aid in determining a reputable supplier.

Conclusion:

Polymer lithium batteries are gaining prominence due to their numerous advantages over traditional rechargeable batteries. Their flexible packaging options combined with excellent stability make them an ideal choice for a wide range of electronic devices. Considering certain usage criteria such as capacity requirements and operating conditions helps in selecting an appropriate polymer lithium battery that ensures reliable polymer lithium battery performance throughout its lifespan.